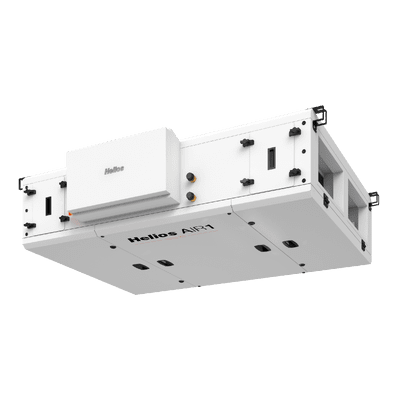

AIR1 XC 3200 R

AIR1 XC 3200 R

Ventilation unit with heat recovery Cross-counterflow heat exchanger, Ceiling version Right-hand version, Electric pre-heater

Ref.-No. 40119

Features

Compact ventilation unit with cross counterflow heat exchanger incl.pre-wired control. For mounting on the storey ceiling or in the false ceiling indoors. Built-in electric pre-heating coil to protect the heat exchanger against frost at very low outside air temperatures. In case of increased comfort temperature requirements, an electric or hot water auxiliary heating coil can be optionally installed in the unit casing. Casing: Made of aluzinc sheet metal, insulated with 50 mm mineral wool for optimum heat and sound insulation. Corrosion-resistant coating on all sides, RAL 7047, corrosion class C4, galvanised on the inside. Inspection openings on the underside of the unit for easy access and optimal cleaning and maintenance. Additional inspection opening on the side for filter maintenance. 2 condensate connections DN 17.5 mm: 1 x exhaust air side, 1 x supply air side. Stainless steel condensate pan with integrated slope. Automatic bypass damper can be activated for free cooling. Temperature sensors for fresh air, supply air, extract air and in the heat exchanger for comprehensive monitoring of the operating status. Eurovent-certified aluminium counter current heat exchanger with a high thermal efficiency of up to 90 % according to EN 308. The heat exchanger has a high internal tightness and is therefore particularly suitable for applications where there may be a risk of odour transmission. Fans: 2 direct-drive EC motors, class IE4 with very low SFP values, dynamically balanced and vibration-damped mounted in the unit. Infinitely variable control via 0-10V signal. Plug-in connections on all electrical components to simplify maintenance work. Filter: Two large-area, pressure loss-optimised cassette filters are fitted as standard (fresh air ePM1 55% (F7) and extract air ePM10 50% (M5)). The use of filters of filter class ePM1 80% (F9) in the fresh air and ePM1 55% (F7) in the extract air is optionally possible. The filter is monitored by means of dynamic, volume flow-dependent pressure monitoring. Control: The ventilation unit is delivered ready for operation with a versatile control system. The control is easy to maintain and is mounted in a terminal box on the side of the unit, factory-wired and function-tested. There is a choice of 2 control elements (ECO and Touch) (accessories required). Control functions: Ventilation modes constant volume CAV, constant pressure VAV (accessory required), constant speed CRPM in % or via weekly programme. Automatic ventilation mode/ Ventilation-On-Demand (VOD) by means of humidity, CO2 or VOC sensors. Up to 18 sensors can be connected per ventilation unit. Free cooling, active cooling by means of cooling coil (chilled water or DX). Temperature control, e.g. constant supply air, outside temperature controlled supply air, room-supply air cascade, etc. possible. Digital inputs for fire alarm and external switch (on / off). Digital output for collective fault signal. External fan control via two analogue 0-10V inputs (supply air and extract air fan separately). Connection to the BMS via BACnet IP or Modbus TCP possible. Commissioning wizards for simple and quick commissioning of the unit and the matching accessories.Additional data and accessories

Technical Data

General Information

| Ref.-No.: | 40119 |

|---|---|

| Type: | AIR1 XC 3200 R |

| Flow rate free-blowing: | 3850 m³/h |

| Voltage: | 400 V , 50 Hz |

| Rated current (FLC) uncontrolled: | 20.9 A |

| Max. air flow temperature: | 45 °C |

| IP protection category: | 31 |

| Weight: | 370,00 kg |

| Unit design: | right |

| Installation position: | ceiling |

| Heat exchanger: | plate heat exchanger |

| ErP-ηt:: | 81,5 % |

| P-qnom (nominal air flow): | 0,76 m³/s |

| Wiring diagram no.: | 1316 |